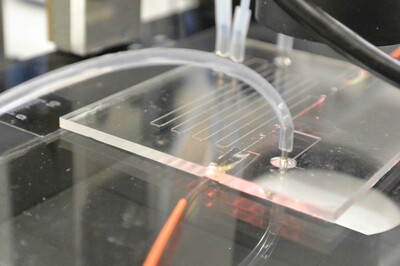

The Laboratory for Microtechnology deals with the simulation, development, production and characterisation of microfluidic systems. These systems produced in the laboratory are used in medical and environmental analysis, among other areas. The focus here is on optical analysis.

Various technologies are available for the production of microfluidic systems. These are: Micro milling (≥30µm structure size), lithography processes (≥1µm structure size), soft lithography (PDMS casting), micro sandblasting (powderblasting), 3D printing (DLP and FDM), PCB-based technologies (PCB MEMS). Fluidic chips are capped or layered by various bonding processes. The combination of fluidics and optics is a key area of expertise. Various methods (including fibre optics) are available for coupling light into the channels.

For the characterisation of the microfluidic systems, in addition to the necessary pumps (syringe pumps / pressure-driven pumps), numerous measurement facilities are available (e.g. spectrometer, various light microscopes, high-speed camera, electron beam microscope with EDX, confocal microscope, AFM).

Use scenarios:

-Simulation, design, fabrication and characterisation of microfluidic systems.

-Training/instruction in fabrication technologies, handling and characterisation of microfluidic systems.

Equipment list:

-Microfluidic manufacturing equipment.

-FLOW EZ™ pressure-based flow control system from Fluigent.

-neMESYS syringe pumps from the company CETONI

-various fibre-coupled LED and laser sources.

-various detector systems and spectrometers.

Software for analysis:

-Comsol